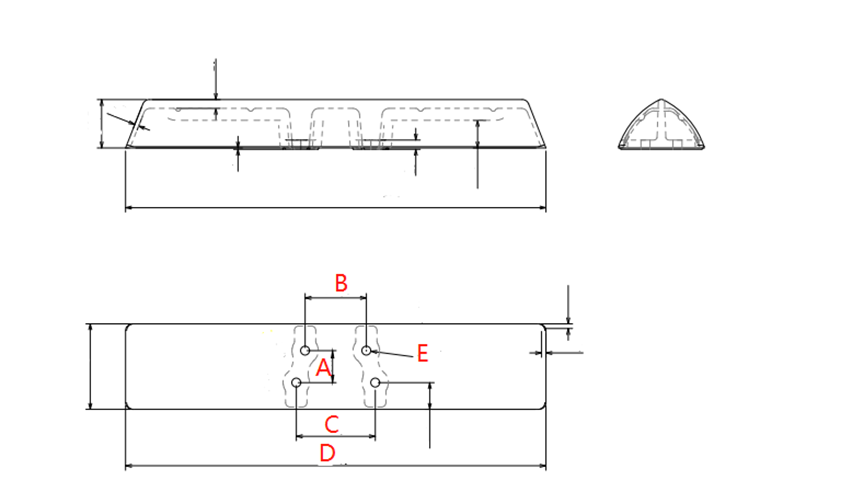

D65 wetland track shoe

Name: wetland track board Model: D 65 950 long Material: 35Mn2

关键词:

D65 wetland track shoe

图文详情

Wetland track plate is the key part of construction machinery working in the wetland environment. The use conditions are extremely harsh, and the mechanical performance indicators such as tensile strength, yield strength, impact toughness and hardness are very high. The current wetland track shoes are produced by cast steel process.

| Name | Wetland track shoe |

| Model | D 65 950 long |

| Material | 35Mn2 |

| Color | Yellow |

| surface hardness | HRC48-55 |

| Warranty period | 6 months |

| Process | Casting |

| Use | crawler bulldozer |

|

BRAND |

CATALOGUE |

||||||||

|

BULLDOZER |

D20 |

D30 |

D31 |

D37 |

D40 |

D41 |

D45 |

D50 |

D60 |

|

D65 |

D68 |

D75 |

D80 |

D85 |

D150 |

D155 |

D275 |

D355 |

|

|

D3C |

D3D |

D4C |

D4D |

D4H |

D5 |

D6C |

D6D |

D6H |

|

|

D6R |

D7G |

D8K |

D8N |

D9N |

D10N |

D11N |

|

|

|

The swamp track shoe, also known as the wetland track plate, is an essential element for construction machinery operating in wetland environments. These unique components face extremely challenging usage conditions, demanding exceptional mechanical performance.

In the wetland, the terrain is often soft, muddy, and full of obstacles, presenting a significant test for any machinery. The swamp track shoe must be robust enough to handle these difficult circumstances. Tensile strength is a crucial factor, enabling it to withstand the pulling forces exerted during operation without deforming or breaking. Yield strength is also essential to ensure that it doesn't give in easily under stress.

Impact toughness is another vital characteristic. When the machinery encounters various obstacles or uneven surfaces in the wetland, the swamp track shoe needs to be able to absorb the impact and prevent damage. A high level of impact toughness allows it to remain intact and functional even in the face of sudden shocks.

Hardness is yet another important aspect. It helps the swamp track shoe resist wear and abrasion, ensuring a longer service life. In the wetland environment, where there is constant friction and contact with abrasive materials, a hard surface is necessary to maintain its integrity.

Currently, most swamp track shoes are manufactured using the cast steel process. This process offers several advantages. It allows for the production of complex shapes with high precision, ensuring a proper fit and functionality. The cast steel material provides the necessary strength and durability to meet the demanding requirements of wetland operations.

The design of the swamp track shoe is also crucial. It is often engineered with specific features to enhance traction and stability in the wetland. Special tread patterns or cleats may be incorporated to improve grip on slippery surfaces. Additionally, the size and weight of the track shoe are carefully considered to distribute the load evenly and prevent sinking or getting stuck in the mud.

Swamp track shoes are not only important for the performance of the machinery but also for safety. A faulty or weak track shoe could lead to instability, breakdowns, or even accidents in the wetland environment. Therefore, strict quality control measures are in place during the manufacturing process to ensure that each swamp track shoe meets the highest standards.