E320 Undercarriage Track Rollers

Model: E320 CAT320 Name: support wheel Material: 50Mn

关键词:

E320 Undercarriage Track Rollers

图文详情

The track rollers are used to support the weight of the tractor when the track link surface rolls, and to restrain the track link to prevent lateral sliding. When the tractor turns, the track rollers force the track links to slide on the ground.

The roller wheel is often in muddy water and dust, and is strongly impacted, so it is required to have a reliable seal and wear-resistant rim.

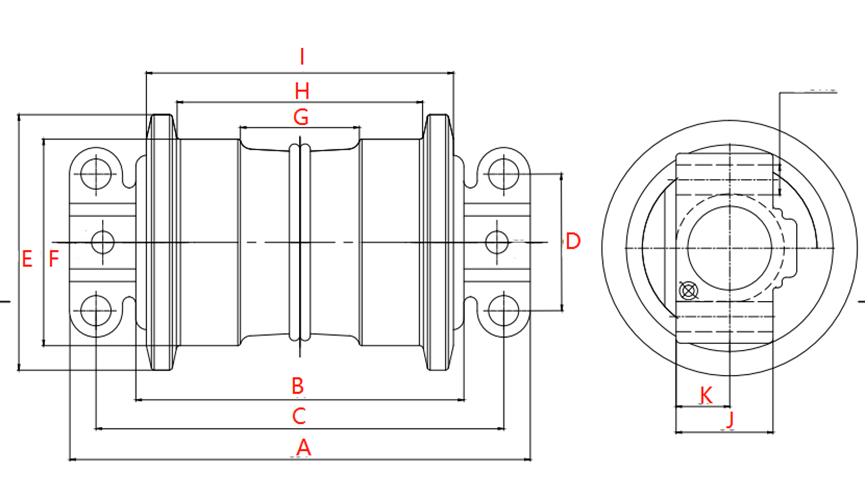

The roller is fixed under the wheel frame with screws to support the mass of the machine and distribute the mass on the track plate. At the same time, it also relies on its roller flange to clamp the chain rail to prevent the crawler from slipping off (derailment) laterally, ensuring that the machine moves along the crawler direction with small rolling resistance and service life in muddy and water operations. According to the structure, the roller can be divided into unilateral roller and bilateral roller. Two types of sliding bearings and rolling bearings are used. The edge of the roller is quenched and its hardness reaches 52-58HRC.

| Model | E320 CAT320 |

| Name | roller |

| Material | 50Mn |

| Process | Forging |

| surface hardness | HRC52-58 |

| Warranty period | One year |

| Mounting dimensions | 98*296 M21.5 |

| Trademark | Shengxiang |

| Certificate | ISO9001 |

| apply | Excavators, cranes, crawler vehicles |

|

KOMATSU |

PC20 |

PC30 |

PC40 |

PC55 |

PC60-1 |

PC60-5 |

PC60-6 |

PC60-7 |

PC650 |

|

PC71 |

PC75 |

PC100-5 |

PC120-5 |

PC200-5 |

PC220 |

PC300-5 |

PC400-5 |

|

|

|

CAT |

E303 |

E305.5 |

E305 |

E307 |

E35B |

E45 |

E50B |

E70B |

|

|

E110 |

E120B |

E135 |

E140 |

E311 |

E312 |

E180 |

E200B |

|

|

|

E215D |

E225 |

E235 |

E320 |

E240 |

E320C |

E324 |

E325 |

|

|

|

E329 |

E325DF |

E300B |

E330 |

E345 |

E365 |

E385 |

|

|

|

|

HITACHI |

EX30 |

EX50 |

EX55 |

EX60 |

EX60-2 |

EX70 |

EX70DF |

EX90 |

|

|

EX100 |

EX120 |

EX100M |

EX150 |

EX200-1 |

EX200-2 |

EX200-5/6 |

EX220 |

|

|

|

EX230 |

EX300 |

EX330 |

EX350 |

EX400 |

EX800 |

ZX270 |

ZX330 |

|

|

|

ZX350LC-3 |

ZX350 |

ZX450-3 |

ZX470LCH-3 |

|

|

|

|

|

|

|

DEAWOO |

DH50 |

DH55 |

DH80 |

DH130 |

DH220 |

DH250 |

DH258 |

DH280 |

|

|

DH300 |

DH500 |

DX30 |

DX35 |

DX55-9 |

DX60 |

DX80 |

DX140 |

|

|

|

DX225 |

DX300 |

DX420 |

DX700 |

|

|

|

|

|

|

|

HYUNDAI |

R35 |

R50 |

R55 |

R60-5 |

R60-7 |

R80-7 |

R130 |

R200 |

|

|

R210 |

R220-9 |

R260 |

R290 |

R305 |

R320 |

R335 |

R455 |

|

|

|

R3450LC-7 |

R460 |

R520LC-7 |

R520-9 |

R954 |

|

|

|

|

|

|

VOLVO |

EC35 |

EC55 |

EC80 |

EC140 |

EC210 |

EC290 |

EC330D |

EC360 |

|

|

EC460 |

EC480 |

|

|

|

|

|

|

|

|

|

KOBELCO |

SK04 |

SK042 |

SK045 |

SK30 |

SK35 |

SK35SR |

SK40 |

SK50 |

SK03 |

|

SK50-AFIE |

SK55 |

SK60 |

SK60-5 |

SK100 |

SK120 |

SK140 |

SK200-3/5 |

|

|

|

SK200-6 |

SK220 |

SK230 |

SK250 |

SK270 |

SK300 |

SK300-3 |

SK320 |

|

|

|

SK07N2 |

SK12 |

SK330 |

SK350 |

SK400 |

SK450 |

SK7055 |

SK03 |

|

|

|

SUMITOMO |

SH60 |

SH60DF |

SH65 |

SH100 |

SH120 |

SH135 |

SH200 |

SH200DF |

|

|

SH260DF |

SH280 |

SH220 |

SH300 |

SH300-A2 |

SH350 |

SH400 |

|

|

|

|

KATO |

HD140 |

HD250 |

HD400-1 |

HD420-2 |

HD450 |

HD550 |

HD700 |

HD770 |

|

|

HD820 |

HD1250-5/7 |

HD2045 |

HQ301 |

HQ302 |

HQ303 |

|

|

|

|

|

OTHERS |

MS110 |

MS180 |

VIO30 |

VIO45-6 |

VIO55 |

VIO65 |

VIO75 |

CX55 |

|

|

CX75 |

JS200 |

JS240 |

JY200 |

BD2G |

DB200 |

GH180 |

GH200 |

|

|

|

JX210 |

YC35 |

YC60 |

YC65 |

YC85 |

SWE50 |

SWE65 |

SWE70 |

|

|

|

SWE75 |

IHI35 |

IHI50/55 |

IHI80 |

T120 |

T140 |

35T |

50T |

|

|

|

70 |

ZN75 |

ZN160 |

BOBCAT C335 |

LONGGONG60 |

Liufang 906 |

908 |

205 |

|

|

|

915 |

920 |

925 |

936 |

60 |

|

|

|

||

|

R914 |

R954 |

PH7035 |

PH7045 |

JD350 |

JD450 |

CX55 |

CX75 |

|

|

|

MGM130 |

GM36 |

CX130 |

SC500 |

U15 |

U35 |

U60 |

U185 |

|

|

|

BR518 |

17760 |

MU500-3 |

ROC07 |

ZBC60 |

NF130 |

DRISOR |

BF200 |

|

|

|

PM200 |

LS118 |

HCR1500 |

TMX20 |

GM80 |

HQ208 |

DX55-9 |

JS14 |

|

|

|

KX91-3 |

VIO17 |

35 |

55 |

75 |

806 |

191936 |

83765 |

|

|

|

Z001S004 |

DH508 |

DSR200 |

SC650 |

U30-2 |

HDQ306 |

HQ307 |

|

|

- Product selling point: Undercarriage track rollers are essential components of the undercarriage system. They provide support, stability, and smooth movement for the tracks, ensuring optimal performance and longevity. These track rollers are typically made from high-quality materials such as forged steel or heavy-duty rubber, offering durability and resistance to wear and tear. They are precision-engineered to withstand heavy loads, vibrations, and harsh operating environments. Undercarriage track rollers often come with features such as sealed or lubricated bearings, ensuring low maintenance and long service life.

- Industry application: Undercarriage track rollers find applications in various industries that rely on tracked machinery or equipment, including construction, mining, forestry, agriculture, and material handling. They are commonly used in excavators, bulldozers, track loaders, pavers, and other heavy-duty equipment. Undercarriage track rollers play a vital role in supporting the weight of the machine, distributing the load evenly, and contributing to smooth and efficient track movement. They are crucial for maintaining stability, maneuverability, and overall performance in demanding job sites or terrains.